Overhead cranes are essential in industries where lifting and moving heavy loads is a daily requirement. They are commonly used in manufacturing plants, warehouses, shipyards, and other industrial settings. However, before making a purchase, it’s important to understand the costs associated with overhead cranes, including the initial investment, installation, maintenance, and long-term expenses. This article will provide a comprehensive guide to estimating overhead crane costs and help you make an informed decision.

Types of Overhead Cranes and Their Costs

The cost of an overhead crane largely depends on the type you choose. There are several different configurations of overhead cranes, each with its own price range:

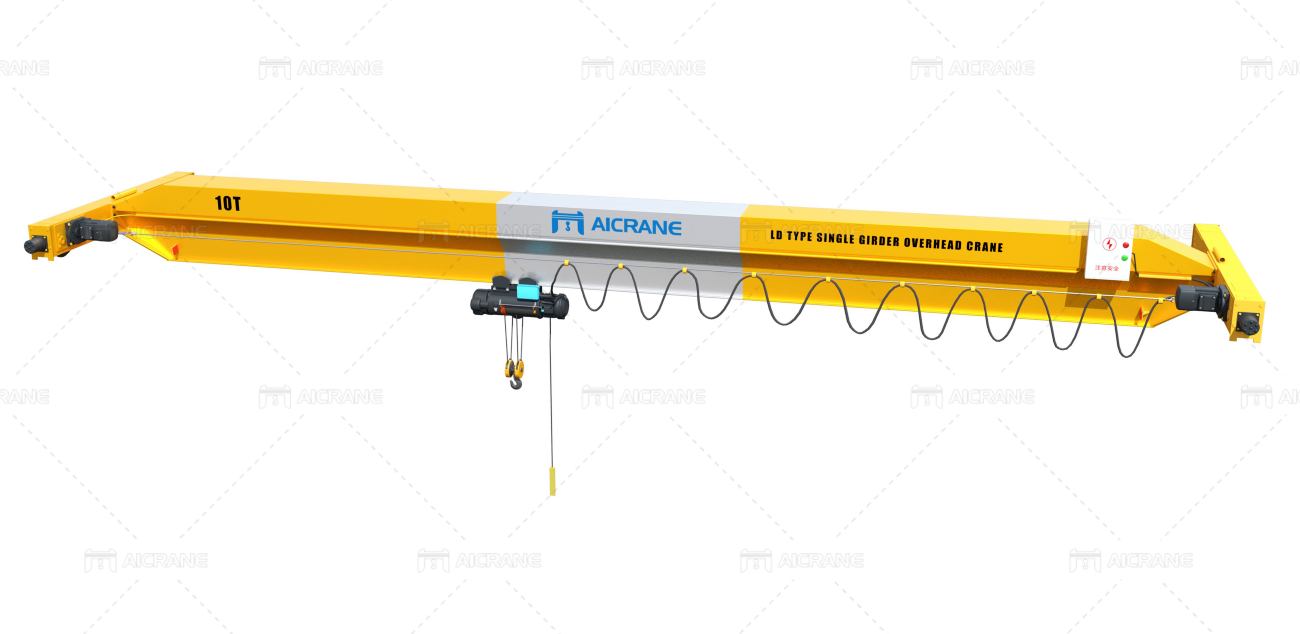

- Single Girder Overhead Crane: A single girder overhead crane features one main beam that supports the hoist and trolley. These cranes are typically used for light to moderate loads and are more cost-effective than double girder cranes. Prices for single girder cranes generally range from $15,000 to $100,000, depending on capacity and span length.

- Double Girder Overhead Crane: Double girder cranes have two parallel beams supporting the hoist and trolley, making them suitable for heavier loads and larger spans. Double girder bridge cranes can lift much higher weights and are often used in heavy-duty industrial environments. The cost of these cranes ranges from $50,000 to $300,000 or more, depending on the required specifications.

- Gantry Cranes: Gantry cranes are similar to overhead cranes but are supported by legs instead of being mounted on the building structure. They are often used for outdoor applications or when overhead space is limited. The cost of gantry cranes varies based on their size and load capacity, typically falling between $20,000 to $500,000.

Key Factors Influencing Overhead Crane Costs

Several factors impact the final price of an overhead crane, including:

- Load Capacity: The greater the load capacity, the higher the cost. Cranes with higher weight capacities require stronger materials and more advanced mechanisms, which increases the overall price. For instance, a crane with a 5-ton capacity will cost significantly less than one designed to lift 100 tons.

- Span Length: The span is the distance between the crane’s supports, typically measured in feet or meters. Larger spans require longer girders and additional structural reinforcements, raising the cost. If your facility requires a crane with an extended span, this will add to the investment.

- Height of Lift: The height of the lift refers to how far the hoist must travel vertically to move a load. Cranes that need to lift materials to greater heights require more powerful hoists and additional safety features, which can increase the overall cost.

- Operational Environment: The environment in which the crane operates can also affect costs. For example, cranes used in harsh environments, such as foundries, chemical plants, or outdoor settings, may require specialized materials like corrosion-resistant steel, heat shields, or other protective measures. These features can add to the cost but are necessary for long-term durability.

- Customizations and Accessories: If your application requires special features, such as advanced automation systems, remote controls, or custom lifting attachments, these modifications will increase the crane’s price. While these customizations can improve efficiency and safety, they should be factored into your overall budget.

Installation Costs

In addition to the cost of the crane itself, you’ll also need to consider installation expenses. Installing an overhead crane is a complex process that involves several steps, including:

- Structural Modifications: The building or facility may need to be modified to accommodate the crane system. This could involve reinforcing the ceiling or walls, installing runway beams, and making other structural changes. The cost of structural modifications can range from $10,000 to $100,000 or more, depending on the extent of the work required.

- Electrical Wiring and Power Supply: Overhead cranes require a dedicated power supply, which may involve additional electrical work to ensure that the crane operates safely and efficiently. The cost of electrical work will vary depending on the complexity of the system, but it typically ranges from $5,000 to $20,000.

- Labor Costs: Professional installation is essential for ensuring the safe operation of your overhead crane. Labor costs for installation vary depending on location, crane complexity, and the scope of the project. Expect to pay anywhere from $5,000 to $50,000 for skilled labor to install your crane.

Ongoing Maintenance Costs

Once your overhead crane is installed, ongoing maintenance is necessary to ensure its safe and efficient operation. Routine inspections, part replacements, and repairs can add to the long-term costs of owning an overhead crane. Key maintenance costs include:

- Inspections and Testing: Regular inspections are required to ensure the crane is functioning correctly and complies with safety regulations. Depending on the frequency and depth of the inspections, you can expect to pay $500 to $3,000 per inspection.

- Parts Replacement: Over time, parts such as hoist cables, brakes, and motors may need replacement. The cost of replacement parts can range from $1,000 to $10,000, depending on the type of crane and its components.

- Repairs and Downtime: Unexpected repairs due to wear and tear or malfunctions can also contribute to the cost. It’s crucial to have a maintenance plan in place to reduce downtime, as extended downtime can impact productivity and lead to lost revenue. Aicrane, as a reliable supplier, offers different overhead cranes with high cost-effectiveness, helping users make the heavy lifting operations easier and quicker.

Estimating Your Investment

To estimate the total investment for an overhead crane, you should consider both the initial costs and long-term expenses. Here’s a simplified cost breakdown:

- Crane Purchase Price: $15,000 to $300,000+

- Installation and Structural Modifications: $15,000 to $150,000

- Maintenance and Repairs (Annual): $2,000 to $10,000+

Depending on your specific needs and crane configuration, the total investment could range from $50,000 to over $500,000 over the crane’s lifespan. While the upfront costs may seem substantial, the long-term benefits of improved productivity, efficiency, and safety often justify the investment.

Investing in an overhead crane is a significant financial decision, but it can dramatically improve material handling operations in industrial settings. By understanding the various factors that influence overhead crane costs—including the type of crane, installation expenses, and long-term maintenance—you can better estimate your investment and plan accordingly. Proper planning and maintenance will ensure your overhead crane delivers reliable performance and value for many years.