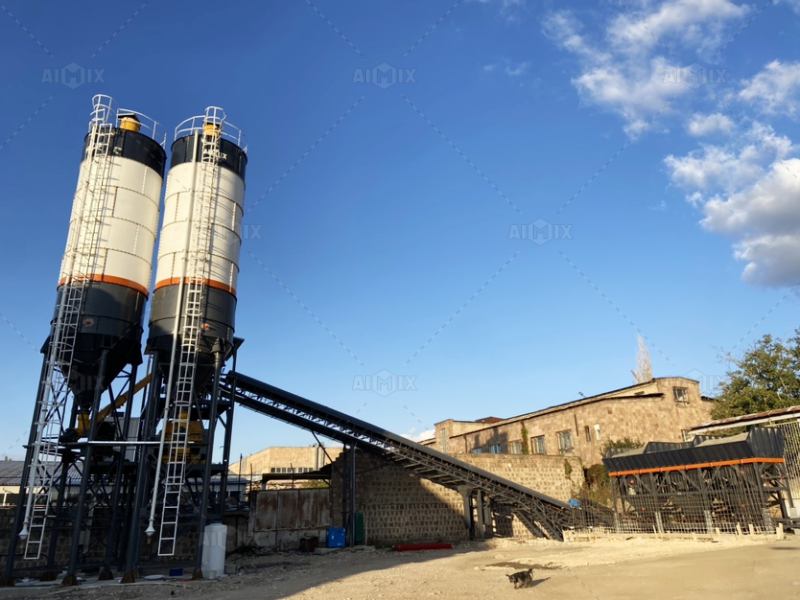

Concrete continues to be a foundational material in the construction sector, fueling urbanization, infrastructure development, and industrial projects across emerging markets and developing countries. For contractors and investors, understanding concrete batching plant cost is crucial for planning, budgeting, and establishing a competitive edge in these rapidly growing regions. Beyond the initial purchase price, factors such as local labor, infrastructure, logistics, and technology adoption significantly influence the total investment in a concrete batching plant business.

This article explores the cost considerations for setting up concrete batching plants in emerging markets, highlighting the influence of plant type, capacity, and sourcing, particularly with China batching plant suppliers.

Overview of Concrete Batching Plant Cost

The cost of a concrete batching plant is not limited to equipment purchase. Investors must account for a range of factors:

-

Equipment cost: Depending on capacity, automation level, and technology.

-

Installation and commissioning: Civil works, foundations, electrical connections, and labor.

-

Operational costs: Utilities, spare parts, labor, and maintenance.

-

Transportation and logistics: Delivery of the plant and raw materials, particularly in remote or developing regions.

In emerging markets, these factors can significantly impact the ready mix plant cost. For example, importing equipment from China may offer lower initial costs compared to domestic suppliers, but transportation, customs, and local infrastructure may increase total expenditure.

Plant Type and Capacity Considerations

Concrete batching plants come in various types, including stationary, mobile, and compact plants, each with different cost structures:

-

Stationary batching plants are ideal for large-scale projects and long-term operations. While the concrete batching plant cost is higher, their capacity and durability provide better ROI over time.

-

Mobile batching plants are designed for flexibility and temporary projects. Their initial cost is often lower, but they may have higher maintenance and fuel expenses in the long run.

-

Mini or compact plants are suitable for small-scale projects and startups, offering lower upfront investment but limited production capacity.

Choosing the right type depends on project scale, local demand, and capital availability. In many developing countries, small to mid-sized plants are popular due to limited urban infrastructure and the need for mobility across multiple job sites.

Influence of Automation and Technology

Automation significantly affects concrete batching plant cost and operational efficiency. Plants range from semi-automatic systems requiring manual supervision to fully automated systems with PLC control, real-time monitoring, and integrated quality control.

-

Semi-automatic plants have lower initial costs but may require more labor and supervision.

-

Fully automated plants increase upfront investment but reduce long-term operating expenses and improve concrete quality consistency.

For a concrete batching plant business in emerging markets, balancing automation with affordability is critical. Many investors opt for moderately automated plants sourced from China to optimize both ready mix plant cost and operational efficiency.

Sourcing from China: Cost Advantages

China has become a major supplier of concrete batching plants to developing countries due to competitive pricing, wide product range, and experience in serving emerging markets. China batching plant manufacturers offer several advantages:

-

Lower manufacturing costs: Reduced material and labor costs make Chinese plants more affordable than European or U.S. counterparts.

-

Flexible customization: Suppliers can adjust plant capacity, automation level, and layout according to client requirements.

-

Spare parts availability: Chinese manufacturers often maintain extensive supply chains for spare parts, reducing downtime.

-

Training and support: Many Chinese suppliers provide on-site installation, training, and technical support, critical in regions with limited local expertise.

However, buyers should account for shipping, customs, and local adaptation costs, which may affect the final investment.

Infrastructure and Operational Costs in Developing Countries

Beyond plant purchase, infrastructure and operational considerations affect total ready mix plant cost:

-

Power supply: In regions with unreliable electricity, plants may require generators, increasing operating expenses.

-

Water availability: Continuous water supply is critical for concrete quality; infrastructure upgrades may be needed.

-

Labor costs: While generally lower in developing countries, skilled operators and engineers may be limited, necessitating training.

-

Maintenance and spare parts: Plants need routine servicing to maintain efficiency; importing parts may add cost if local supply is limited.

Addressing these factors is essential for ensuring the plant’s long-term profitability and sustainability.

Establishing a Concrete Batching Plant Business

Investing in a concrete batching plant business in emerging markets requires careful planning. Considerations include:

-

Market demand: Urban growth, infrastructure projects, and housing developments drive aggregate demand.

-

Regulatory compliance: Environmental and safety regulations may influence plant location and design.

-

ROI calculation: Initial concrete batching plant cost must be balanced against expected revenue, operational savings, and market opportunities.

By selecting an appropriately sized plant with moderate automation, sourcing from a reputable China batching plant manufacturer, and optimizing local operations, investors can achieve a competitive edge in the market.

Conclusion

The concrete batching plant cost in emerging markets and developing countries is influenced by multiple factors, including plant type, capacity, automation, sourcing, infrastructure, and operational challenges. While upfront investment is important, long-term operational efficiency, maintenance, and supply chain considerations often have a greater impact on profitability.

Sourcing plants from China can reduce initial costs and provide reliable support, making it a popular choice for investors establishing a concrete batching plant business. By carefully planning capacity, automation, and local operations, contractors can minimize ready mix plant cost while ensuring consistent, high-quality concrete production.

For developers and entrepreneurs in emerging markets, investing in a well-chosen concrete batching plant offers both economic and operational advantages, positioning them for growth in a rapidly expanding construction sector.