It wasn’t long ago that I started hearing about tire to fuel plant. This idea was quite intriguing to me as I had always done my best to make smart and environmentally friendly choices. It all started when I was in high school and visited a local landfill. I was astonished by the amount of trash that just one rather small community was creating. I began to learn more about ways we could lower our waste and encourage others to recycle. The path I was on led me to the many different uses of recycled items, including plastics.

While we are becoming better at recycling as time progresses, there is still a lot of work that needs to be done. The current rate of recycling plastic items is about 25 percent, which rises a little each and every year.

Doing all we can to recycle plastics is important. Unlike paper, wood, and other materials we use on a regular basis, plastic degrades very slowly. It is quite durable and the molecular bonds that make it that way are resistant to degradation. Nearly one billion tons of different plastics have been trashed since the 1950’s. Yes, we are seeing more recycled, but we are also using more. More information on tyre pyrolysis plant here.

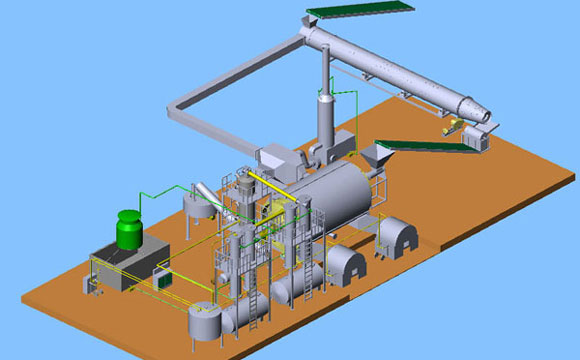

In order to create fuel from waste plastic, the process involves heat. In order to convert plastic into oil, the long chain polymer molecules that make up plastic are broken into shorter chains with heat and pressure. Basically, it is similar to how the Earth naturally breaks down carbon into oil, but the Earth’s job takes much longer, like a million years longer. The process of pyrolysis is able to use enough heat and pressure inside a closed system, containing no oxygen, that it only takes a short amount of time.

Once the plastics’ molecules are “broken”, a liquid is produced. This is liquid is pyrolysis oil. Once the oil is created, it can be stored or transported. The pyrolysis waste plastic to fuel oil can be used as is, or it can be refined even further and turned into jet or diesel fuel.

As excited as I am about the new technologies that arise every day, it is still a bit disheartening that we are still throwing so much into our landfills, oceans, and other areas where there should be no trash. Conversion of plastic waste to fuel oil is a great start to finding alternate uses for the items we once thought were trash. I know as we are on this planet longer, this will become a more efficient process that we can use for many different things. Get pyrolysis machine cost here.